总部位于澳大利亚的解剖学是早期在手术中使用3D打印的先驱。在神经外科医生保罗德乌索(Paul D’Urso)的领导下,该公司在个性化植入、手术计划和3D打印医疗设备方面做了大量工作。在胸外科、CMF植入物和整形外科,该公司推出了软件解决方案以及供外科医生使用的植入物和材料。患者专用手术工具、患者专用脊柱笼、胸骨或设计手术植入物的软件。

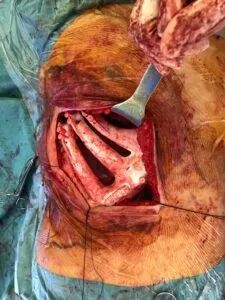

现在,解剖学家与新加坡的Tan Tok Seng医院合作,进行了世界首创的聚合物胸腔镜重建术。使用解剖的StarPore聚合物组织支架,一名需要新胸腔的26岁癌症患者得到了帮助。手术很成功,病人两天后就回家了。除了3D打印的胸腔重建术本身之外,还创建了针对患者的手术指南,医学模型以及切割指南和模板,以辅助手术。

StarPore具有“强度、灵活性及其允许细胞和组织向内生长的能力”。StarPore脚手架将维持患者的寿命,同时保持其形状不变,并用天然组织将其固定在适当的位置。由于生物小梁的孔隙率与人体相似,该材料为人体组织提供了一个可以抓紧并生长的支架。”

这项手术由谭托克森医院胸外科主任阿内兹·艾哈迈德博士和他的团队进行。艾哈迈德博士表示,

“在这种情况下,没有与StarPore解决方案相提并论的东西。由于没有其他选择,因此StarPore解决方案绝对可以改善患者的健康状况……Anatomics解决方案的一个重要优点是易于使用。我们不再像传统方法那样一次做一根肋骨,而是切开并分离了患处的胸壁,轻松地插入了植入物,从而使重建变得非常容易。“解剖学个性化解决方案的帮助取得了成功。通常的胸壁重建平均需要大约4-6个小时。我们能够在大约两个半小时内完成此案例”

长期以来,针对患者的植入物一直被吹捧为植入物和骨科的未来。从理论上讲,它们应该导致更快的手续,更少的失血和更快的恢复时间。在某些情况下,这可能是正确的,而在其他情况下,标准植入物就足够了。然而,对于新颖的手术程序,将3D打印与数字化手术计划相结合已成为一条通往未知和重大新成果的久经考验的道路。此处看到的集成方法将使该过程有些不适,并使执行计划更加清晰。我认为,第一次合适的东西是有价值的,但绝对知道个性化的切割指南和特定的标签是有价值的,以确保减少错误;特别是长时间的、新的或复杂的程序。

标记:3D打印胸腔•解剖•聚合物•聚合物植入物

Singapore: World’s First 3D Printed PolymerRibcage Reconstruction

Australia based Anatomics was an early pioneer in using 3D printing forsurgeries. Under Neurosurgeon Paul D’Urso the firm has done a lot of work in personalized implants,surgical planning and 3D printed medical devices. In thoracic surgery, CMFimplants and orthopedics the firm has rolled out software solutions as well asimplants and materials for surgeons to use. Patient-specific surgical tools,patient-specific spinal cages, sternums orsoftware to design surgical implants.

Now Anatomics worked with Singapore’s TanTok Seng Hospital to do a world-first, a Polymer ribcage reconstruction. UsingAnatomics’ StarPore polymer tissue scaffold a 26 year old cancer patient whoneeded a new ribcage was helped. The surgery was a success and the patient wenthome after two days. In addition to the 3D printed ribcage reconstruction itself,patient-specific surgical guides, medical models and cutting guides andtemplates were also created to aid the surgery.

The StarPore has, “strength, flexibility and its capacity to allow cell andtissue ingrowth. StarPore scaffolding will last for a patient’s life spanwhilst keeping the same shape, with natural tissue holding it in place. Thematerial provides a scaffold for human tissue to grab onto and grow into, dueto biological trabecular porosity similar to that found in the body.”

The surgery was conducted by Dr Aneez Ahmed,Head of Service of Thoracic Surgery at Tan Tock Seng Hospital, and his team. DrAhmed says that,

“There’s nothing like a like for like comparison with theStarPore solution for this case. Thus the StarPore solution definitely improvesthe patient’s health outcome as there is no alternative possible…An importantadvantage of the Anatomics solution was the ease of use. Instead of doing onerib at a time, multiple times, in the conventional way, we cut out and detachedthe affected chest wall and inserted the implant easily, making thereconstruction very easy. “The Anatomics personalized solution (StarPoreimplant, BioModel, 3DP cutting guide and 3DP implant positioning template)helped achieve the success. The usual chest wall reconstruction takes anaverage of about 4-6 hours. We were able to do this case in about two and ahalf hours”

Patient-specific implants have long been touted as the futureof implantology and orthopedics. Theoretically, they should result in quickerprocedures, less blood loss and faster recovery times. In some cases, this maybe true while in others a standard implant could suffice. In the case of novelprocedures however 3D printing coupled with digital surgical planning isbecoming a tried and tested route to the unknown and big new results. The integratedapproach seen here would derisk the procedure somewhat and make planning anexecution much clearer. I would assume that there would be value in somethingfitting right the first time but absolutely know that there is value inpersonalized cutting guides and specific labeling to make sure that errors arereduced; especially with lengthy, new or complex procedures.

— 长按关注增材之光 —